Our hardware

solution

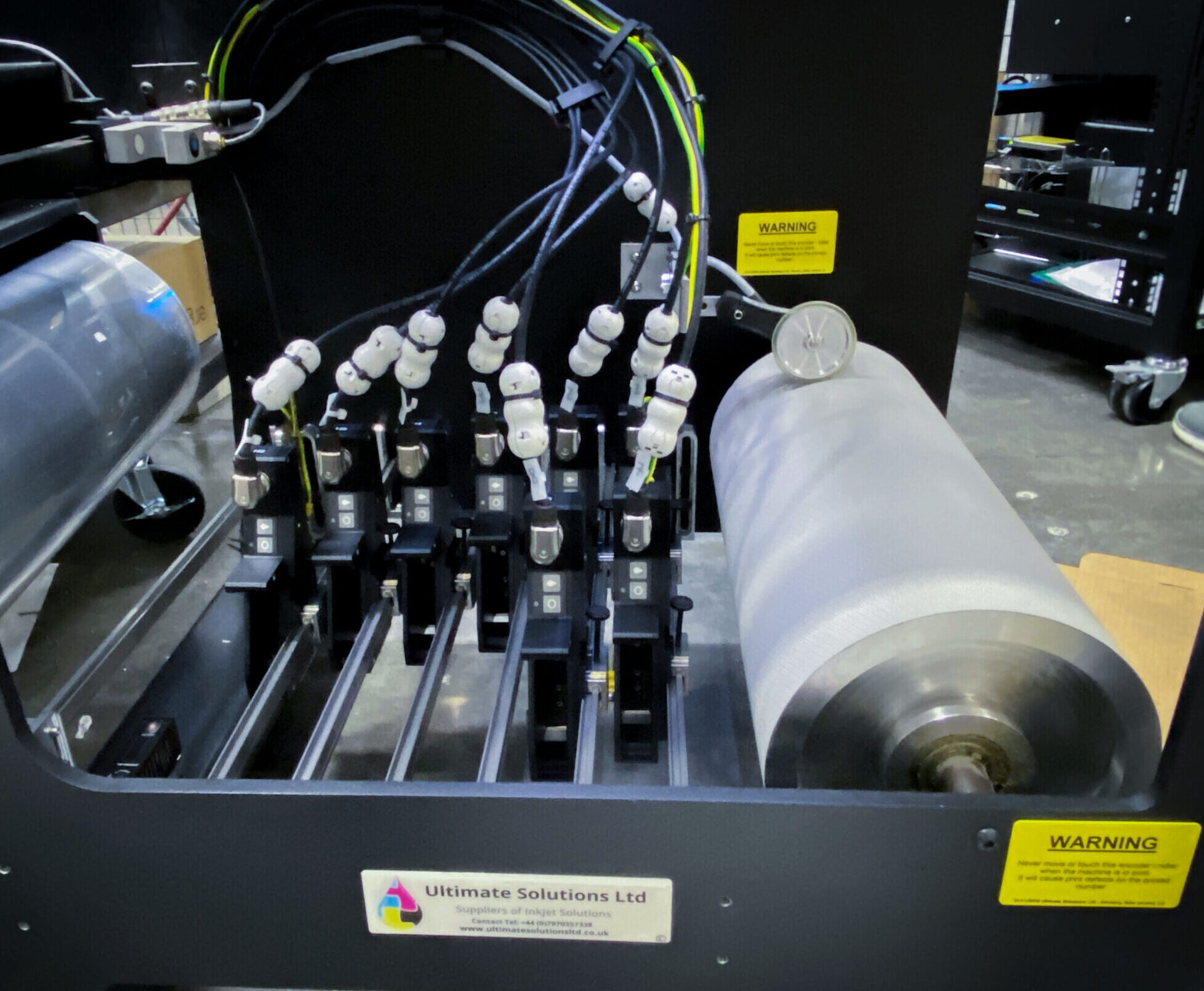

Ultimate choose to supply TIJ2.5 Thermal Inkjet Technology

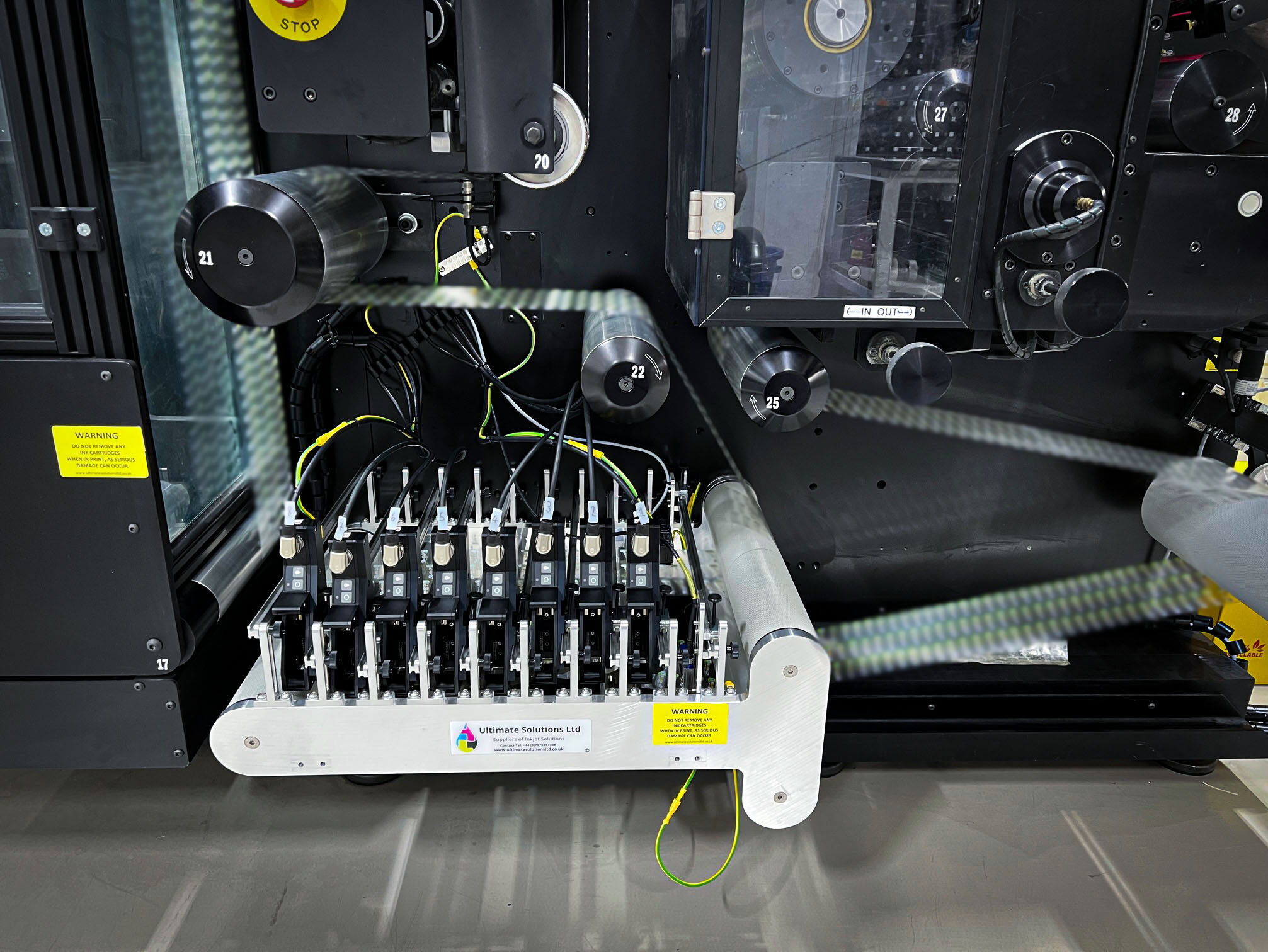

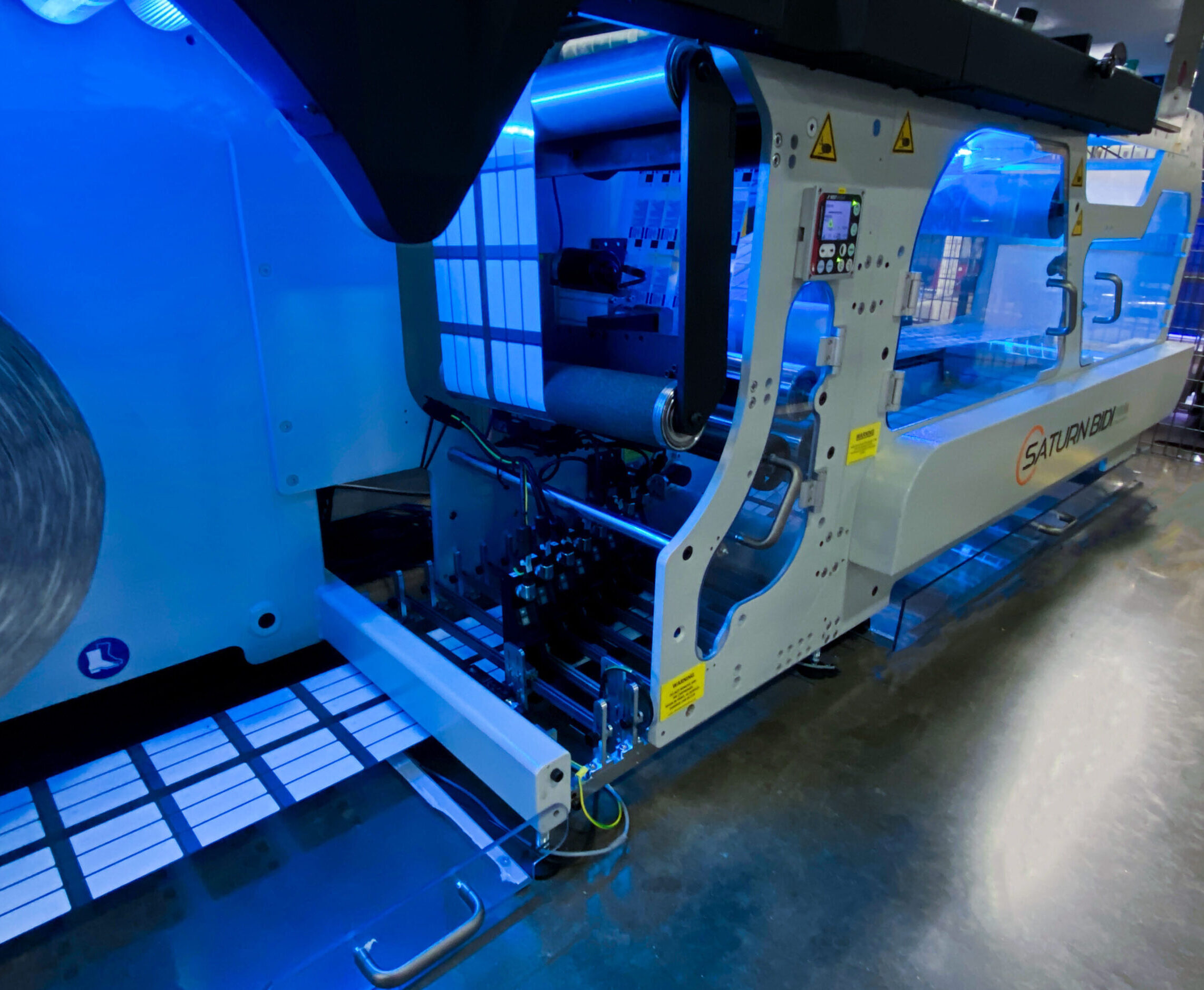

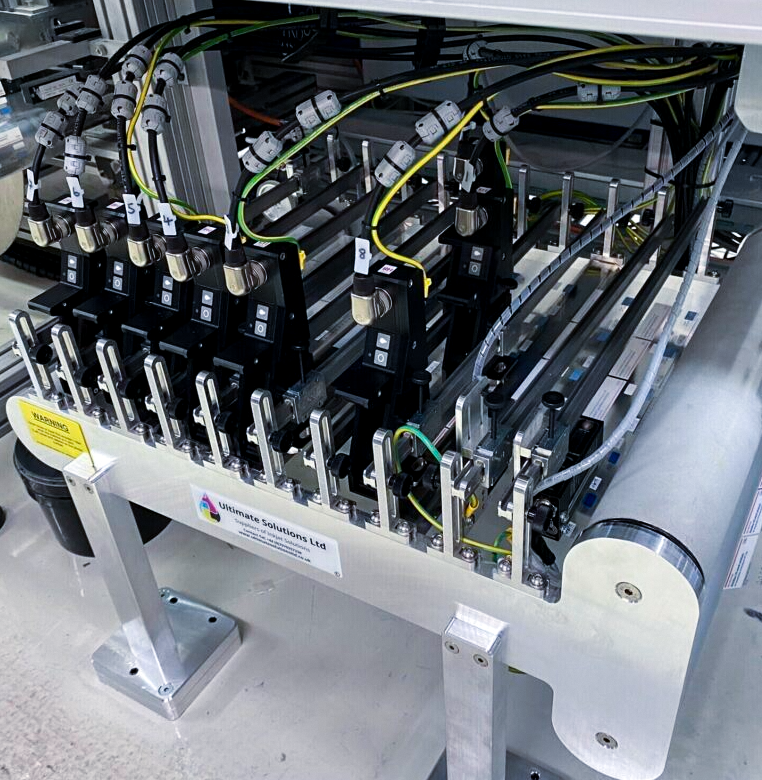

We provide a comprehensive range of numbering solutions, from modular units to bespoke frameworks, tailored to fit your finishing machine. Our solutions are adaptable and can be seamlessly integrated into your equipment.

We also offer a variety of ink types, including water-based, solvent, UV invisible, and UV cure inks.

Advantages

Plug & Play technology

Easy to install / small foot print

Multiple Head configurations

From 1 to 16 heads / lanes per system

Ink Laydown controllable

No set off

Clean & easy to use technology

No make ready + Access to +200 different cartridge types whether printing onto glassine or filmic materials. + Wipe and print.

High Speed

300dpi x 300dpi – 152 mpm / 498.6 feet per minute.

Small drop size/ Courier Font + Reduces offsetting / save on consumables / thinner font

less ink, more labels per cartridge

and Better drying

Ability to run from a variable data file or database

Good reliability

Zero downtime

Ink reduction tools that do not compromise speed

Easy set up software

Enter the basic label repeats and the software automatically does the rest

Full logging software

Jobs are easily tracked for audit purposes.

Bespoke Solutions Using TIJ Technology

We have built a micro processor that detects the size of each label & gap by measuring the print

signals from the label sensor, as well as encoder pulses. If no ‘print go’ trigger is seen from the label

sensor then we automatically insert a trigger pulse which means no gaps in the sequence number.

Passionate About Support

1 to 2 year Guarantee on Hardware & Remote Team viewer Support.

We provide a 1 or 2 year warranty on all the products that we supply, which means

the hardware will be replaced if it fails.

Support is provided through Team viewer should any software support be needed

on site remotely.

The hardware is plug & play. If a head fails simply replace the faulty head & return it

to base for repair.

For detailed information about our products, including pricing, please contact us at: